Paper Authors and Title

Ciara Fitzpatrick (Technological University of the Shannon), James J. Roche, “Total Organic Carbon Analysis of Residual Contaminants in Bioreactor Equipment: A Cleaning Verification Study using Surface Swabbing”

Abstract

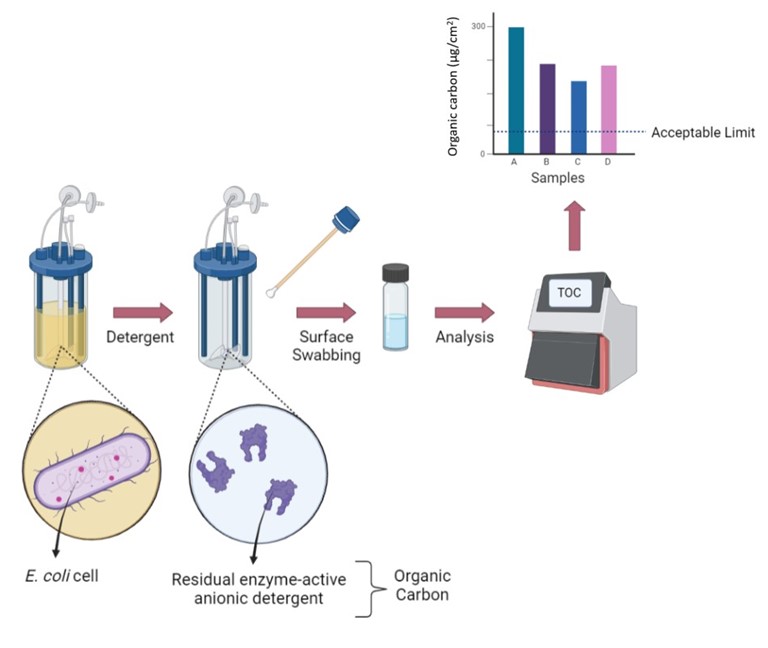

Contamination is a major issue in the biopharmaceutical industry. Bioreactors must be meticulously cleaned to remove residual contaminants and avoid cross contamination. Bacterial cells represent the “worst-case scenario” in manufacturing equipment cleaning because they are composed of insoluble organic contaminants. Total organic carbon (TOC) analysis is a fast, highly sensitive, and inexpensive analytical technique commonly used to evaluate the approximate level of organic contamination.

TOC analysis was used to assess the effectiveness of cleaning procedures in the removal of organic contaminants from bioreactor equipment. A high-density culture of Escherichia coli JM109 cells was obtained, and a popular enzyme-active anionic detergent was chosen to clean the equipment surfaces. The areas selected for swab sampling included the borosilicate glass vessel and stainless-steel impeller blades.

The acceptance limit for the quantity of residual contaminants present on the surfaces of the bioreactor was calculated to be 7 μg/cm2. The values obtained from this study were all significantly above this threshold. Strikingly, the stainless-steel blades were found to have the highest levels of contamination with a value of 295 μg/cm2.

The high quantities of organic contaminants present on the bioreactor equipment surfaces were attributed to the detergent that was used during the cleaning procedure. This finding suggests that the use of this detergent in bioreactor equipment cleaning could potentially result in the contamination of the subsequent manufactured product, which could negatively affect its safety and quality. In conclusion, the results of this study highlight the importance of cleaning verification, small-scale experimentation, and detergent selection.