Paper Authors and Title

Micah Nicole Imperial (Technological University Dublin), Declan McCormack, Joseph Mohan, Sinead Currivan-Macdonald, “Investigation of UV processing & post-cure conditions on the mechanical properties of 3D DLP printed polymer resins”

Abstract

Aims

The aim of this project was to investigate the properties of 3D printed polymer resins such as tensile strength, hydrophobicity, and fracture toughness as a result of changing post-cure conditions in the hope that 3D printed resins could be used for purposes such as replacement parts in machinery. Four photopolymer resins were chosen from Elegoo: Plant-Based, Water-Washable, ABS-like, and Standard, chosen to determine the most suitable for long-term usage and the effect of a co-polymer.

UV Cure Investigation

Through investigation via mechanical testing, FTIR, and SEM, it was determined that a 0-10 minute UV cure was insufficient for the photopolymer resins as the cure station was at a 45o angle to the samples, resulting in a surface-level cure. There was minimal difference in strength between the cured and uncured samples.

Thermal cure Investigation

The effect of a thermal cure was investigated, and the higher temperature (60oC) after a 5 minute UV cure produced an up to 75% increase in strength. The stability of the cured resin was tested with water immersion, where hydrolytic degradation occurred later at 60oC after 2 hours but occurs immediately at 30oC. The increase of both the temperature and time of the thermal cure also resulted in increasing hydrophobicity of the samples. For the water washable samples, there was an initial 58o water contact angle but a 46o water contact angle was observed at 60oC after 24 hours without water immersion, and a more hydrophilic surface than the thermal cure at 62oC for the water immersed sample.

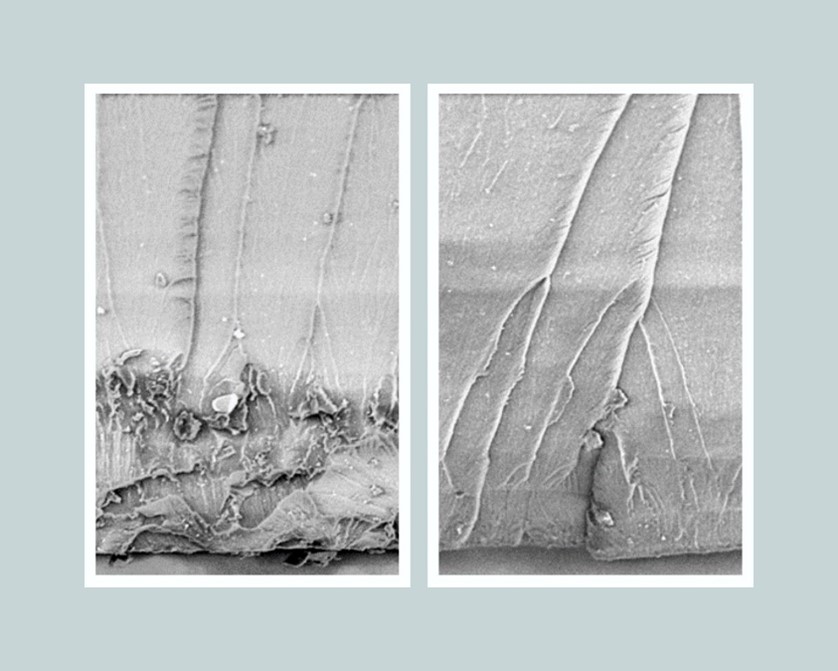

Figure 1. SEM at x1000 magnification of water washable resin after a 24 hour cure at 60oC with no immersion (left image) and water immersion (right)